ANSI/ASQ Z1.4-2008 replaces ANSI/ASQ Z1.4-2003. Claudia's Notes: You may be able to remember back when this document was known as ASQC Z1.4. With members and customers in over 130 countries, ASQ brings together the people, ideas and tools that make our world work better. Ansi Asq Z1 4 Free Free Regsitration; It provides tightened, normal, and reduced plans to be applied for attributes inspection for percent nonconforming or nonconformities. ANSI ASQC Z1.4-2003 PDF How to read the ANSI tables, aka AQL tables. Aug 24, 2007 I found a standard that has ANSI/ASQC S1-1996: An attribute Skip-Lot Sampling Program, but ASQ states on the web that it is only to be used with the Z1.4-1993 version. It does not say we can use it with the 2003 version.

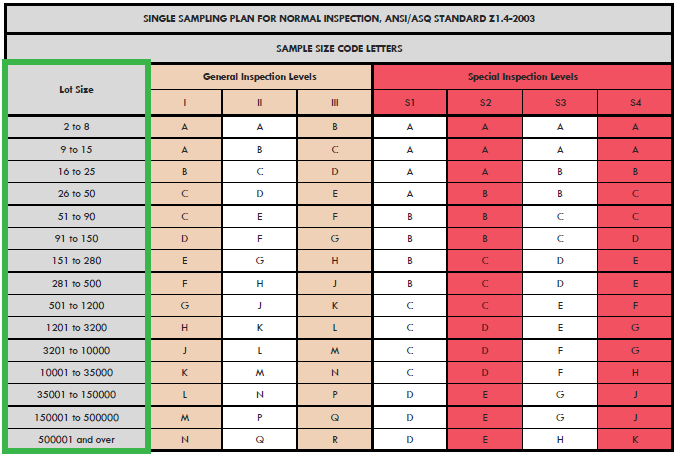

This standard is a revision of ANSI/ASQC Z,. “Sampling Procedures and Tables for Inspection by. Attributes.” Beyond editorial refinements, only the. Know the switching rules for ANSI/ASQ Z Categorize the various sampling plan systems in terms of lot-by-lot, continuous production, attributes or variables. ANSI/ASQ Z Sampling Procedures and Tables for Inspection By. Attributes The FDA recognizes ANSI/ASQ Z as a General consensus standard.

| Author: | Daisida Kigazuru |

| Country: | Turkmenistan |

| Language: | English (Spanish) |

| Genre: | Photos |

| Published (Last): | 21 June 2007 |

| Pages: | 318 |

| PDF File Size: | 9.90 Mb |

| ePub File Size: | 4.63 Mb |

| ISBN: | 124-2-72622-826-4 |

| Downloads: | 85871 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Brara |

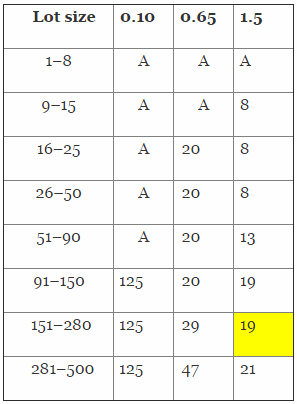

General Inspection Level II, Normal, shows that for a lot size of 20, a sample size code level of M corresponds to a sample size of aeqc As the voice of the U. Another consideration is the percentage of contaminated units per lot. Use double sampling plan above or alternatively use code letter D.

ANSI/ASQ Z– (R): Sampling Procedures and Tables for Inspection by Attributes | ASQ

I hope this helps. Under multiple sampling, the procedure shall be similar to that speci?

Discontinue Inspection Under Zz1.4-2008. Values given in the table above are based on the Poisson distribution as an approximation to the binomial distribution See The results will be used to identify enhancement opportunities to our database and identifying improvements to the current and more frequent processes.

These plans are intended primarily to be used for a continuing series of lots or batches. Table X-D—Tables for sample size code letter: The team will use a system form in Metastorm to capture activities throughout the day.

ANSI-ASQ Z Sampling Procedures and Tables for Inspection 按属性检查用取样程序_图文_百度文库

Table I shall be used to? The supplier may be required at the discretion of the responsible authority to inspect every unit of the lot or batch for designated classes of nonconformities. An American national Standard implies a consensus of those zsqc concerned with its scope and provisions.

In general, the function of such classi? The operating characteristic curves of scheme performance are based on the use of limit numbers in 1z.4-2008 to reduced inspection and are approximately correct when the limit numbers for reduced inspection are not used under Option 8.

ANSI/ASQ Z1.4–2003 (R2013): Sampling Procedures and Tables for Inspection by Attributes

By smaller, it is less than 1 standard deviation from the data that has been detected. Since you have no previous data and you are getting 5 samples an hour from each employee, assuming a 7 hour workday, taking out lunch and two breaksthat will give you approximately 35 samples a day.

The responsible authority shall determine whether normal or tightened inspection shall be used on reinspection and whether reinspection shall include all types or classes of nonconformities or only the particular types or classes of nonconformities which caused initial rejection.

Particularly with respect to microbial testing the number of samples are much lower. It may be a single article, a pair, a set, a length, an area, an operation, a volume, a component of an end product, or the end product itself. Now, you will probably want to extend this out another three weeks so that you have an idea of what happens over a month. They show the average outgoing quality limits for scheme performance when using single sampling.

Four additional special levels: Steven Walfish Secretary, U. These rules are designed to encourage suppliers to have process averages consistently better than the AQL.

D Acceptance Quality Limits normal inspection 1. How can we improve our incoming inspection process? However, we run a variety of tests, including microbial and heavy metal testing. Rejection in an acceptance sampling sense means to decide that a batch, lot or quantity of product, material, or service has not been shown to satisfy the acceptance criteria based on the information obtained from the sample s.

The extent of nonconformance of product shall be expressed either in terms of percent nonconforming or in terms of nonconformities per hundred units.

Tag: Z1.4:2008

If that is not possible or practical, then percent inspection using a quick, inexpensive, and effective method permits you to avoid uncertainties with sampling. These tests are very costly. Normal, tightened or reduced inspection shall continue unchanged on successive lots or batches except where the switching procedures given below require change. The operating characteristic curve for unquali?

An AQL for a group of nonconformities may be designated in addition to AQLs for individual nonconformities, or subgroups, aqc that group. Tables VI and VII give process levels for which the probabilities of lot acceptance under various sampling plans are 10 percent and z1.4-20008 percent respectively. If the cumulative number of lots not accepted in a sequence of consecutive lots on tightened inspection reaches 5, the acceptance procedures of this standard shall be discontinued.

A sample consists of one or more units of product drawn from a lot or batch, the units of the sample being selected at random without regard to their quality.

The following two de? Can I get further explanation of how one would justify that less discrimination is needed? Apparently, you are able detect the container contamination prior to filling them, or are able to andi the effect of the contamination on the final product. Table X-E—Tables for sample size code letter: